Why Labeling is Challenging on High-Speed Beverage Lines

Label application may appear simple, but in real-world bottling operations, labeling is one of the most error-prone and visually sensitive steps on the line. At high speeds, even minor inconsistencies in label material, container shape, or adhesive performance can lead to skewed, wrinkled, or missing labels.

Because of these challenges, many plants struggle to assure that every container has a correctly placed, undamaged, fully adhered, properly printed label.

Continue reading to learn how to find a solution to these issues.

How Label Inspection Solves These Problems

Common label inspection issues include:

-

High line speeds & throughput pressures

At 20,000+ bottles per hour, there’s very little margin for error. Any slight deviation in placement, alignment, or print quality gets magnified. -

Variability in container orientation, shape, and surface

Containers may rotate or wobble, surfaces have curvature, varying diameters or shoulder shapes, and slight tilts can cause label misalignment. -

Shrink sleeves, wrap-arounds, or glue-on labels have different behaviors

Shrink sleeves can wrinkle, lift, or stretch; glue-on labels can misalign, wrinkle, or partially detach; wrap-arounds may not fully adhere at seams. - Regulatory, branding, and consumer expectations

Misplaced, missing or defective labels can lead to noncompliance (e.g. missing warnings, barcodes, lot codes), product recalls, or negative brand perception. -

Inspection “blind spots” and limited coverage

Traditional inspection systems often inspect only one side or use limited-angle cameras, leading to uninspected portions (seams, back label, overlaps)

Modern label inspection systems transform labeling from a reactive to a proactive quality control process. Using advanced vision technology, 360° coverage, and intelligent image analysis, label inspection ensures every container leaving the line is properly labeled and visually flawless.

By identifying issues such as skew, misalignment, missing labels, or print defects in real time, operators can correct problems before they impact production efficiency or product quality.

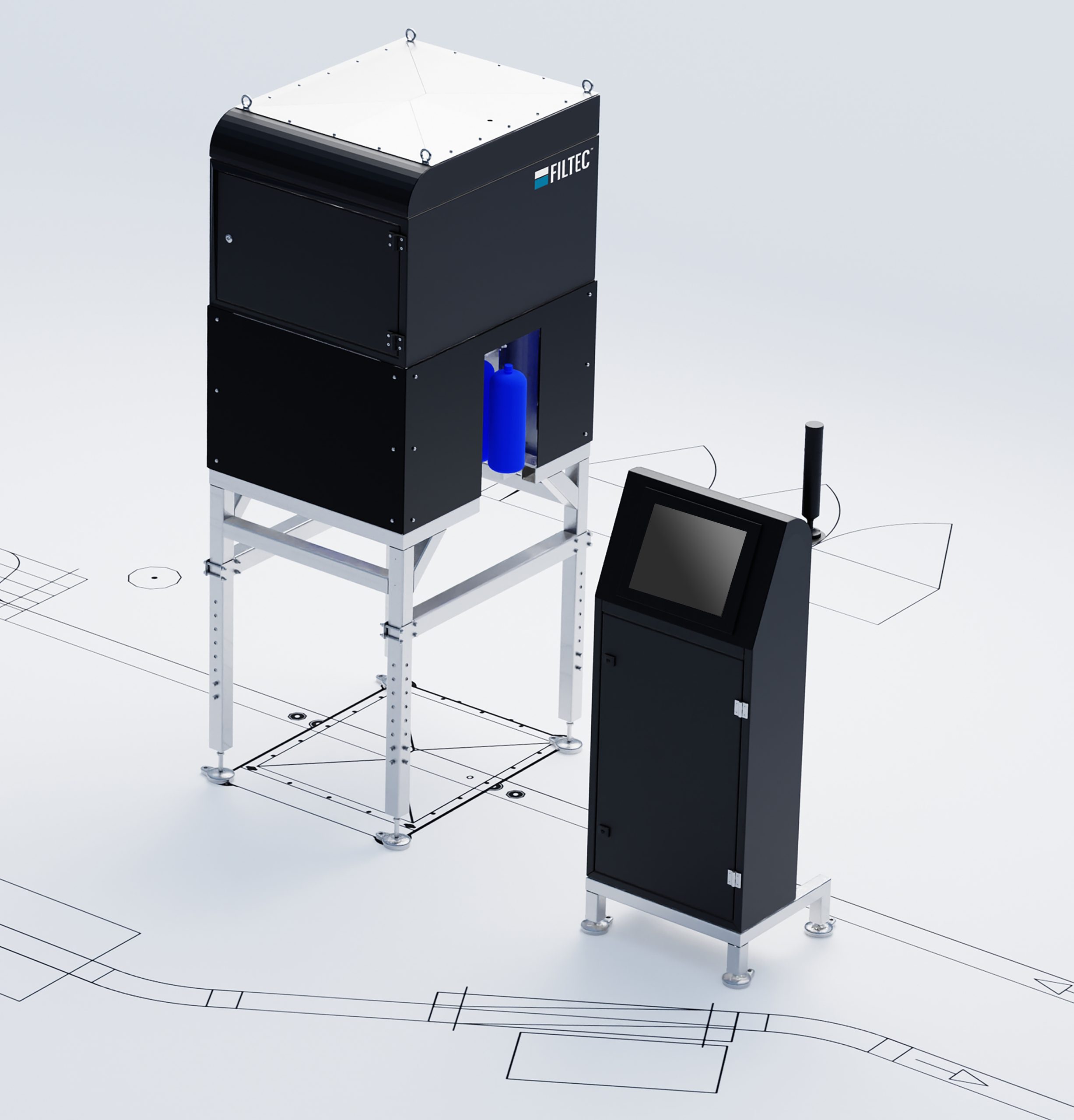

Filtec OmniLabel 360 – 360° Vision for Label Accuracy

-

Full 360° inspection coverage: Multi-angle, overlapping high-resolution cameras capture all sides of non-oriented containers—no blind spots, no missed defects.

-

High throughput support: OmniLabel 360 is built to operate at speeds up to 50,000 bottles per hour, making it suitable for very high-speed production lines.

-

AI-driven inspection & deep learning: Advanced algorithms adapt to variations in label graphics, shrink materials, and container differences, improving detection accuracy and reducing false rejects.

-

Self-teaching setup & auto-calibration: Smarter changeover and easier setup are possible thanks to calibration tools and adaptive learning.

-

User-friendly HMI / touchscreen interface: A Windows-based graphical touchscreen interface ensures operators can monitor, configure, and review inspection results with ease.

-

Versatile label type support: Supports both shrink labels and wrap-around (glue-on) labels in one system—even on non-oriented bottles.

-

Traceability and data capture: Because OmniLabel 360 is part of Filtec’s broader inspection ecosystem (e.g. with INTELLECT data integration), it can feed inspection results, reject statistics, and trends into your line analytics.